Uncategorized

Precision Metal Stamping Die Manufacturing – Ritech Solutions Vietnam

Ritech Solutions specializes in metal stamping die design and manufacturing according to JIS/DIN standards. With CNC machining accuracy of ±0.01 mm, surface grinding, flatness inspection, and 100% dry assembly before delivery, Ritech ensures high precision and reliability for every die set.

What Is a Metal Stamping Die?

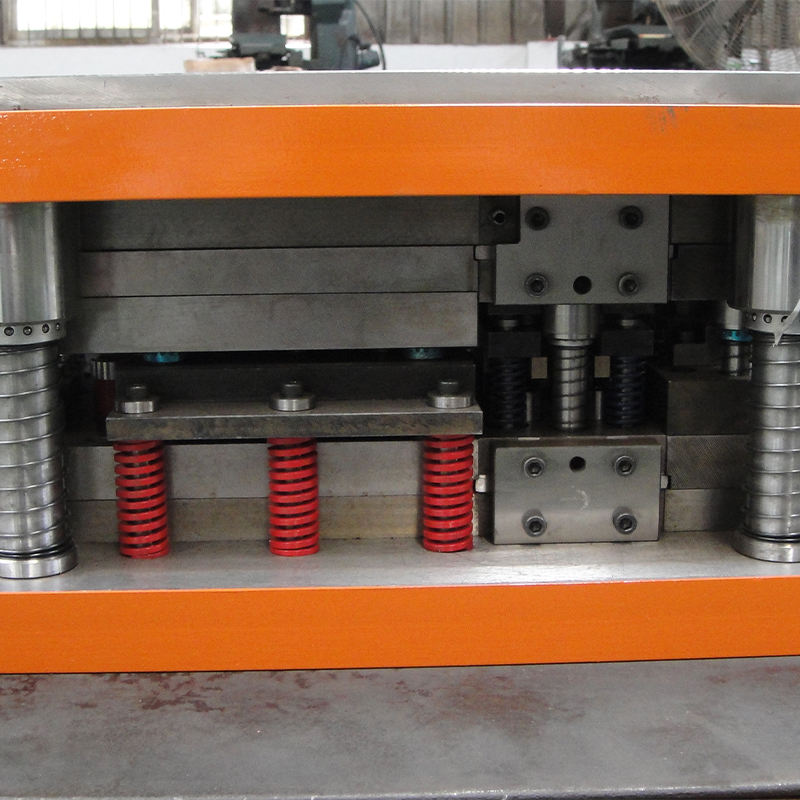

A metal stamping die (also known as a press die or die set) is a precision tool used in mechanical or hydraulic presses to form sheet metal into the desired shape. Dies are essential for producing high-volume metal components with consistent accuracy and quality. Each die typically includes:

- Upper and lower plates (punch holder and die holder)

- Guide posts and bushings for precise alignment

- Punches and dies that define the final shape of the part

- Stripper plates and backing plates for stability and rigidity

Because metal stamping dies are responsible for shaping materials to micron-level tolerances, the machining and assembly process must ensure accuracy, repeatability, and long tool life.

Ritech’s Capabilities in Metal Stamping Die Manufacturing

At Ritech Solutions, we combine advanced CNC machining technology and skilled craftsmanship to deliver world-class metal stamping die sets. Our facility in Hai Phong, Vietnam, serves clients in the automotive, electronics, and precision tooling industries.

Machining Process

- High-precision CNC milling (3–4 axis) with tolerance up to ±0.01 mm

- Surface grinding for superior flatness and parallelism

- Boring, drilling, and reaming of guide holes to JIS/DIN standards

- Threaded hole machining, reaming, and counterbore finishing

Inspection and Quality Control

- 100% dry assembly inspection before shipment

- Flatness verification on granite surface plates

- Parallelism and perpendicularity testing

- Guide post and bushing alignment check using precision pins

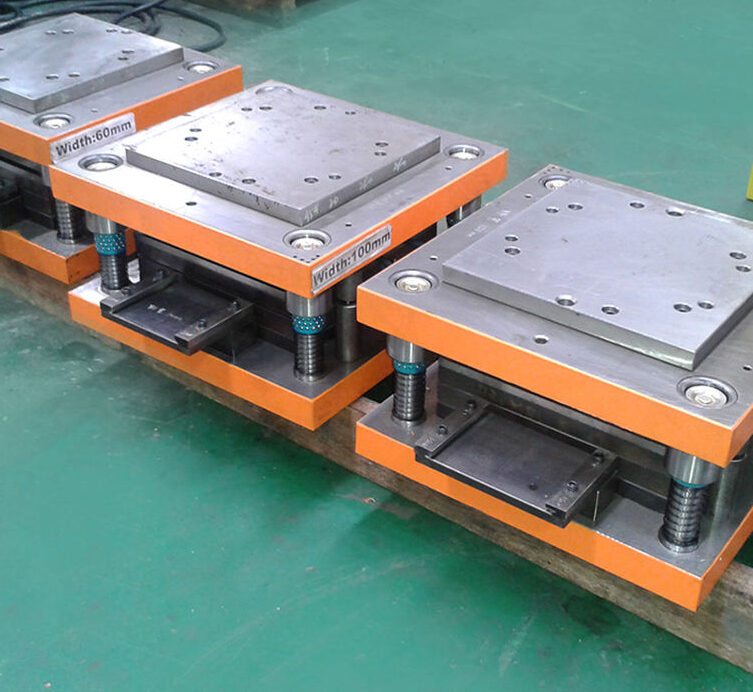

Material Options and Sizes

- Materials: S50C, SKD11, SKS3, FC250 (with heat treatment certification)

- Standard sizes: 200×300 mm | 300×400 mm | 400×600 mm (custom dimensions available)

- Custom machining available per drawing or 3D CAD model

Applications of Metal Stamping Die Sets

Our metal stamping dies are used across industries that demand repeatable accuracy and durability:

- Progressive stamping dies for multi-stage forming

- Compound dies for simultaneous blanking and bending

- Precision cutting and punching dies

- Tooling for automotive brackets, terminals, and housings

- Electronics and appliance component manufacturing

Why Choose Ritech Solutions

- Japanese-level machining precision and QC process

- Competitive production lead time and flexible customization

- Experienced team for die assembly and maintenance

- Full documentation and inspection reports

- Responsive technical support in English, Vietnamese, and Korean

For reference on international tooling standards, visit

Wikipedia – Metal Stamping Process.

Future of Metal Stamping Die Manufacturing in Vietnam

Vietnam is rapidly becoming a hub for precision machining and tooling. Ritech Solutions aims to be among the top-tier manufacturers offering cost-effective, high-precision metal stamping die solutions that meet global quality standards while maintaining local production flexibility. With growing demand from Japanese and Korean manufacturers, Ritech continues to expand capacity, improve automation, and deliver better value to partners worldwide.

📞 Liên hệ

Ritech Solutions – Precision Machining & Jig Design

🏭 Hoàng Lâu, Hồng Phong, An Dương, Hải Phòng

📞 Hotline/Zalo: +84866.972.199

🌐 Website: ritechsolutions.com.vn

Keywords: metal stamping die, die set manufacturing, precision machining, Vietnam manufacturing